Pump Mechanical Seals

Not only are we distributors for some of Europe’s leading pump manufacturers, but we are also distributors for some of the UK’s leading pump mechanical seal manufacturers.

We carry a large stock and are distributors for a large number of Pump and Motor manufacturers. Please call us for any specific make/model you may require on 0116 2897908.

Roten Mechanical Seals

The manufacture of Roten mechanical seals can be traced right back to 1945. The company began under the name Laboratorio Elettromeccanica Di Precisione Carlo Fontanella. (a bit of a mouthful) But in 1974 the company changed its name to Roten S.r.l. and has continued under that name ever since.

Roten seals are now a common name in the pumping world, and can be found sealing some of the most popular types and makes of European pump such as Calpeda, Lowara and Ebara.

We keep a wide range of both Roten 3 and Uniten 3 seals in various face and elastomer combinations, to cover most pumping applications, and can recommend alternative materials should the seal experience premature failure due to either high temperature, abrasion or chemical attack.

Other popular Roten UK seal types stocked are :

Type 52, Type 21, Type 21A (American), Type 51, Type 16, Type 68, Type RO3, Type UN3, Type 37BR, Type 37BS, Type UN5K

We carry a large stock of Roten seals, please call us now on 0116 2897908 with your requirements

Vulcan Mechanical Seals

Founded in 1987 with six production sites based in three different continents, Vulcan Seals have established new leading industry standards with their vast product range, quality, ex-stock service and competitive pricing.

We stock various types and sizes of Vulcan seal to cover many different pumping mediums such as :

Hot wort for both large breweries and micro breweries.

Recycled water in quarries and concrete plants.

Mineral oils for lubrication applications.

Various acids and alkalis in manufacturing processes.

Soluble oil and water emulsions for engineering factories.

Hot water for heating applications

Ethylene and propyl glycols for chiller applications.

To enable a mechanical seal to handle these various liquids, there are numerous types of material the seal can be manufactured from, which will ensure long life and good reliability. This is why we always ask our customers for details of the liquid to be pumped, so that we can be sure we are offering the best seal for the job.

You’d be surprised just how often some we can extend the life of a pump seal just by changing either the face or elastomer (rubber) combinations around.

We can also supply mechanical seals from manufacturers such as Burgmann, Floserve, Latty, Sealol, John Crane and AES.

We carry a large stock of Vulcan seals, please call us now on 0116 2897908 with your requirements

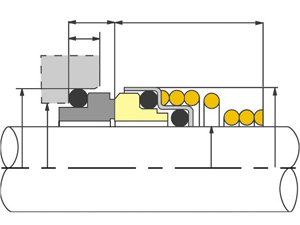

How a single spring mechanical seal works

In the most simplistic terms, a mechanical seal requires four main components/forces in which to operate.

Primary sealing surfaces, secondary sealing surfaces, a means of drive and a means of actuation.

The primary sealing surfaces are the two lapped seal faces that make contact with each other, one stationary and the other rotating. Common seal face combinations are usually one hard face (Ceramic, Silicon Carbide or Tungsten Carbide) and a softer face (usually Carbon). The rotating face, which is usually the harder of the two, is driven (in some cases by the tang of a conical spring), and sealed on the shaft with an internal o-ring. The stationary face will have either a rubber boot or o-ring around the circumference (secondary sealing surface) and is pressed into the back of the pump casing. Pressure (actuation) is then applied to the back of the rotating face by the spring, and the two faces will run together usually lubricated by the liquid being pumped.

The cross sectional drawing clearly shows where the sealing areas are.